CCD vision small parts particles counting and packaging machine

Small parts particles visual counter machine can count pieces of objects for batch packaging by utilizing image processing technology through one wide track all at once , there is no need to separate parts one by one before counting. Unique advantage of our visual bulk counting machine is high accuracy and efficiency. Visual solutions function with such accuracy and precision, which can be applied as alternatives to weighing or pick-and-place systems.

Working principle:

High speed CCD camera scans objects that fall from vibrating chutes to obtain full projection images through optimized algorithm, machine will count number of falling objects so as to realize the batch counting and packaging.

For Example: preset to package 500 screws in one bag.

Hoist lifts screws and pours into feeding hopper, screw fall from vibrating plate, CCD camera catches image and starts counting, computer control system will automatic change vibrating frequency to let just 500 screws fall into pocket, and then pour into packaging machine for bag making and packaging.

Advantage of Visual counter:

- High efficiency: Vision based counter uses large track and scan falling objects , instead of using several narrow tracks to separate objects one by one.

- 99.99% accuracy

- Insensitive to dust

- Fast changeover: One button operation for clearing to change objects

- Self-learning software:Easy to calibrate for multiple objects counting

- Extremely low maintenance

- Reducing labor cost

- Compacted design to save space

Field of application:

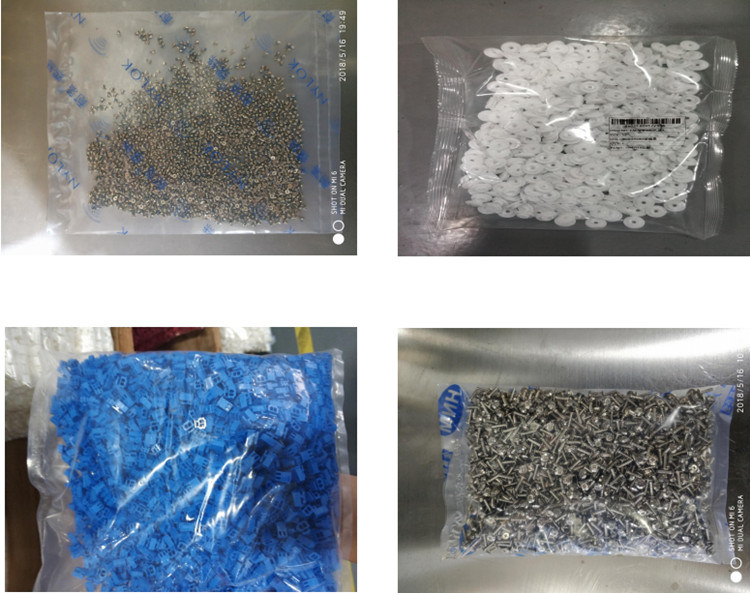

- Electronic components: screws of cellphone or hard disc, capacitor, electric resistance,relay silver contact, electric connector

- Plastic injection molded parts: pipe fittings, plastic parts, garment buttons

- Hardware: nuts and bolts, screws, washer, rivet, nuts, pins, stud

- Fastener

- Agriculture: Seeds,flower bulbs, dry vegetable

- Medicines: capsules,tablet,soft gel, pill

- Food: sweet, candy, frozen food

Technical characteristics and Specification:

- High frequency CCD sensor, scanning frequency at 10,000 times per minutes,six million pixels optical lens with minimum recognition size of 0.2mm.

- Advanced large capacity FPGA processing and control system, response time at 1 nanosecond.

- Optimized algorithm software effectively identifies overlapping objects and micro impurity.

- Industrial tablet computer with touch screen makes it easy to store program for different objects.

- Intelligent alarming system for abnormal situation and shortage, screen will appear tips.

- Patented self-learning technology can achieve to count different objects easily.

- One button clearing function.

- Connectable to ERP system.

- Tailing materials collecting channel is optional.

Bulk package Demo

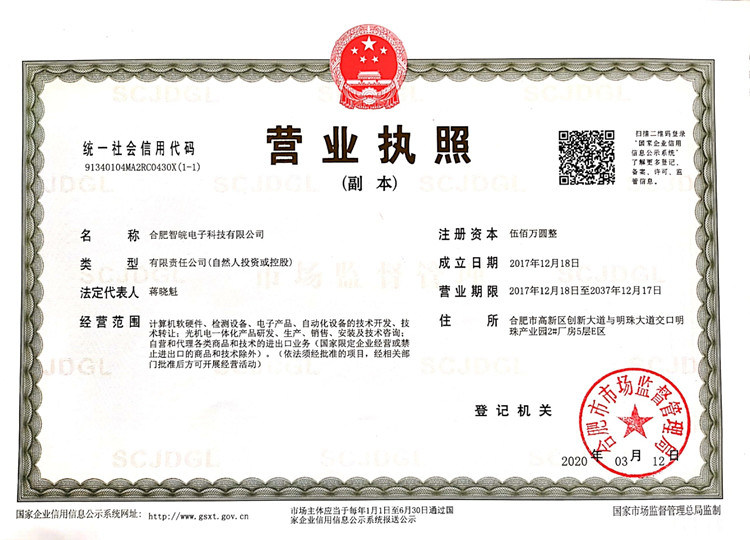

Business license

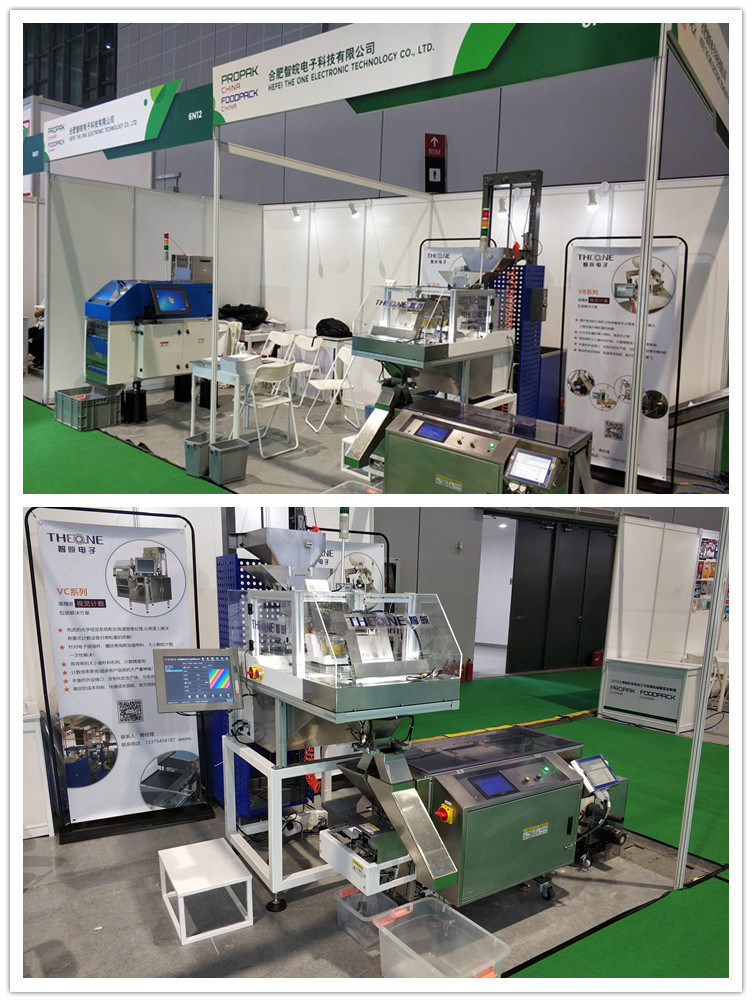

Fair Show